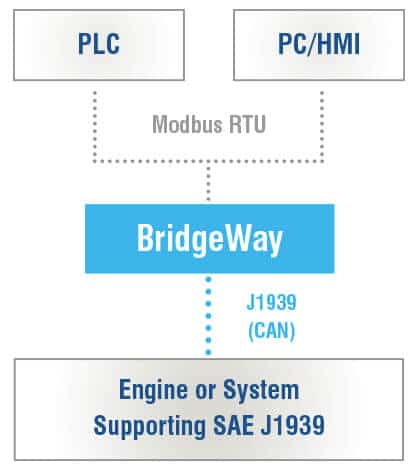

Our BridgeWay™ J1939 to Modbus RTU Interface (Part# BW2031) provides connectivity between a Modbus RTU (RS485 serial 2 wire) network and a J1939 (CAN) network. The gateway operates as a Modbus RTU Slave device, allowing a Modbus RTU Master to read and write J1939 PGN data.

We provide a free downloadable Windows-based configuration tool (BWConfig). This PC-based software allows users to map J1939 parameter (PGN) data into the device I/O table memory, which is accessible from a Modbus RTU Master as Modbus registers.

Configuration of our gateways is easy with BWConfig. It consists of setting up an I/O table containing the J1939 PGNs you wish to read or write, and determining the rate at which each will be read or written from/to the J1939 network. BWConfig maps the I/O table to a range of Modbus registers accessible from the device Modbus RTU interface. Users download the configuration from BWConfig to the device via a USB connection. It saves in Flash memory. You can also upload an existing configuration from the device for comparison or to update the configuration.

While not required to configure the device, our optional CANable Lite and MasterSim Lite software tools can also be used to setup and troubleshoot your application using the BW2031.

For more information, please visit our BW2031 Support/Downloads Page. From there you can download the spec/datasheet, user manual, BWConfig configuration software, application examples, starter configurations and much more.

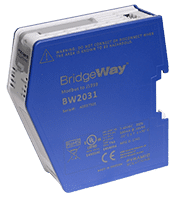

BW2031 BridgeWay Gateway

Specifications

- Dimensions: 110 x 35 x 101 mm / 4.33 x 1.38 x 3.98 in

- Operating voltage: 7 – 40 VDC

- Operating temperature: -25°C – 70°C

- Current requirements: 300mA at 24 VDC

- Mechanical rating: IP20 NEMA rating 1

- Approximate weight: 184g

- Certifications:

- UL certification: UL 61010-1 and UL 61010-2-201

- ATEX certification: EN 60079-0 and EN 60079-15

- CE certification: EN 61000-6-2 and EN 61000-6-4

Features

- Configurable so the user can specify which J1939 PGN messages the module should transmit or receive

- Modbus RTU support for 4800, 9600, 19200, 38400, 57600 and 115200 baud rates

- Supports SAE J1939 vehicle protocol and Modbus RTU (Slave) industrial automation protocol

- Works with Modbus RTU Master PLCs, HMIs and other devices

- Configuration via free Windows-based software tool (BWConfig 2.0) – save, edit and load configurations

- Uses standard USB cable for configuration (USB to micro-USB)

- Supports Flash field upgrades

- LED network and module status indicators

- Includes DIN rail mount

- Brand label/OEM options

Downloads

Click here to go to our BW2031 Support Page to download the BWConfig configuration tool, application guides and user manuals or to get support.

Optional Accessories

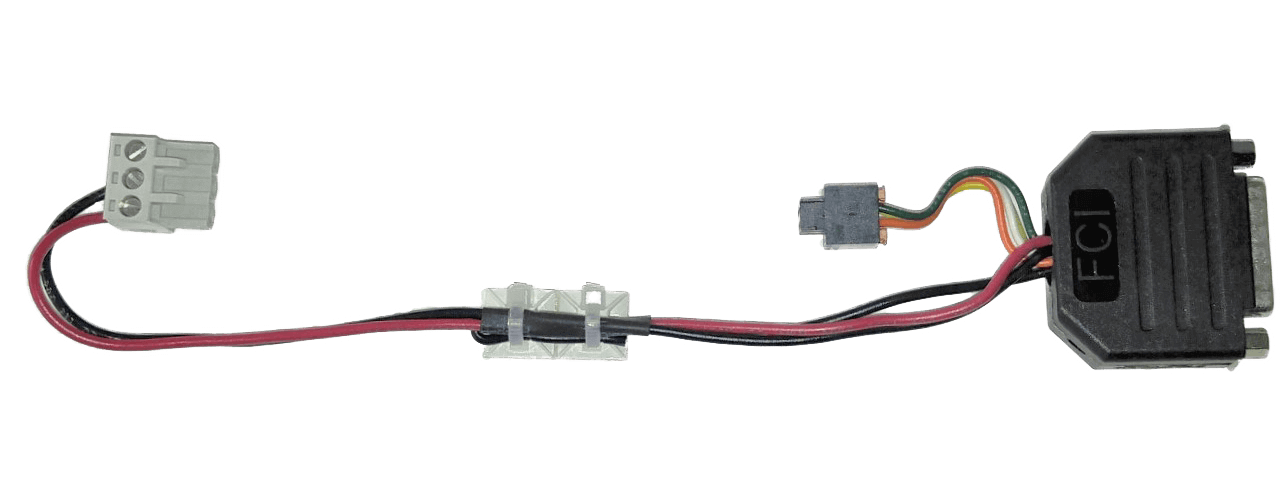

BW2031 Migration Wire Harness (Part No. BW2031-MH)

Allows direct connection to existing BridgeWay 1.0 (AB7606) device

Allows direct connection to existing BridgeWay 1.0 (AB7606) device- Plug the existing 15 pin D-sub connector into the migration harness, import your AB7606 configuration file, download it and you are up-and-running in minutes

CANable Lite – PGN Monitor Package (Part No. CANable Lite)

This quick and easy PC-based software tool is used to view PGN messages on a J1939 (CAN) network which is critical for integrating or troubleshooting an installation. The CANable Lite package includes:

- USB to CAN adapter

- CANable Lite PC/Windows software

- User manual

MasterSim Lite – Modbus RTU Master Simulator (Part No. MasterSim-BW2031)

Used to test Modbus Master connectivity and data mapping without using a PLC/HMI, etc. This tool is critical for integrating or troubleshooting an installation. The simulator includes:

- USB to RS485 Adapter

- MasterSim Lite PC/Windows Software

- User manual

FAQs

What is included with the device?

Our BridgeWay 2.0 J1939 to ModbusRTU supports the following:

- J1939 (125k, 250k, and 500k)

- Modbus RTU Slave (RS-485 2-wire 4800 to 115200 baud)

What is required, but NOT included?

- A properly-wired and terminated J1939 network

- A properly-wired and terminated Modbus RTU (RS485 2 wire) network

- A Modbus RTU Master device (PLC, HMI, etc.)

- Proper 24 VDC power

- A PC or laptop to run the BWConfig 2.0 tool

- A Micro USB to USB cable to connect a PC-running BWConfig2.0 to the BridgeWay 2.0

Can I use one BW2031 to read/write PGN messages on two or more J1939 engine networks?

To achieve this, one BW2031 module would be required for each J1939 engine network. The BW2031 can then have the same J1939 (CAN) address on each individual J1939 network but the host (Ethernet, Modbus RTU, or PROFIBUS) address will have to be unique for each gateway if using a single PLC to read and write data.

Can the device poll other Modbus RTU Slaves?

What J1939 PGN messages does the BW2031 support?

Legacy

AB7606 BridgeWay Gateway

Specifications

- Mechanical dimensions: L=4.96″ (126mm); W=4.30″ (109mm); H=1.65″ (42mm)

- Approximate weight: 16 oz.

- Operating voltage: 11 – 32 VDC

- Current requirements: 93-95 mA at 24 VDC

- Operating temperature: 0 – 70° C

- EMC compliance: EN50081-2 and EN50082-2

- Certifications: CE and cULus

- UL certification: E203225, Listed 67AM, UL-1604 Class 1, Div 2, GP A, B, C, D, Temp code T4

- ATEX certification: ATEX 135419, II 3 G, EEx nL IIC T4, DEMKO 03

Features

- Interface/gateway between PLC/HMI/PC/System and J1939 network

- Configuration via free Windows-based software tool (BWConfig)

- Supports Flash field upgrades

- LED network and module status indicators

- DIN (includes DIN rail mount)

- Rugged extruded aluminum enclosure

- Brand label/OEM options

- Supports SAE J1939 (CAN) and Modbus RTU Slave (serial RS485)

Downloads

Click here to go to our AB7606 Support Page to download the BWConfig configuration tool, application guides and user manuals or to get support.

Optional Accessories

AB7606 Configuration Kit (Part No. AB7606-CFG)

- 3 meter 25-to-9 pin serial cable used to configure the module with BWConfig software

- Latest version of AB7606 User Manual, BWConfig software, application notes and sample configurations

The AB7606 15 Pin Connector and Backshell Kit (Part No. AB7606-CON)

The kit contains the material needed to connect AB7606 to a J1939 Network, Module Power and Modbus RTU RS485 network:

- 15 pin D connector with numbered solder cups

CANable Lite – PGN Monitor/Viewing Package (Part No. CANable Lite)

Used to view the PGN messages on a J1939 (CAN) Network (necessary for integrating or troubleshooting an installation).

- USB to CAN Adapter

- CANable Lite PC/Windows Software

- User Manual

MasterSim Lite – Modbus Master Simulator for the AB7606

Used to test Modbus Master connectivity and data mapping without using a PLC/HMI, etc. (necessary for integrating or troubleshooting an installation).

- USB to RS485 Adapter

- MasterSim Lite PC/Windows Software

- User Manual