When you get up close to the factory floor, you’ll find devices harmoniously communicating together in real-time, thanks in a big way, to EtherNet/IP — a widely-supported protocol used by manufacturers globally.

EtherNet/IP was developed by Rockwell Automation as a call to fulfill the standard required for industrial factories. Currently EtherNet/IP is managed by ODVA (Open DeviceNet Vendors Association), and has been one of the proven, best-in-class networks for the Industrial Internet of Things (IIoT).

What is EtherNet/IP?

Developed in the late 1990s and released in early 2000, EtherNet/IP (Ethernet Industrial Protocol) is an application layer protocol that defines devices on a network as a series of objects. EtherNet/IP is one of several network protocols that operates under the common industrial protocol (CIP), an open application layer protocol. This protocol more recently has been extended to include CIP Security, which provides secure communications between devices on the factory floor. There are other CIP extensions as well, that include CIP Safety, CIP Energy, CIP Sync, and CIP Motion, each of which perform a specific service for the protocol.

EtherNet/IP is not to be confused with Ethernet. While they’re both protocols, they work in different ways.

Ethernet vs. EtherNet/IP

If you use the Internet, chances are you are familiar with the term Ethernet, as the hard-wire connection; however, that is just the simplest way to describe it. Ethernet is a physical networking protocol that is used commonly for commercial use. While Ethernet works well with local- and wide-area networks, it’s not very efficient for industrial factories that require more.

After the wide implementation and success of Ethernet in commercial use, Industrial Ethernet was born to support industrial infrastructure. EtherNet/IP is one type of Industrial Ethernet; others include Modbus TCP/IP, EtherCAT and PROFINET.

Note that Industrial Ethernet, and particularly EtherNet/IP, differs from standard Ethernet; the most important difference being real-time efficient communications. Ethernet and TCP/IP directly provide this, while EtherNet/IP does in conjunction with a managed switch based infrastructure. On the factory floor, you must have real-time efficient communications to maintain control and for accessing real time data to meet production and quality standards.

How EtherNet/IP Works

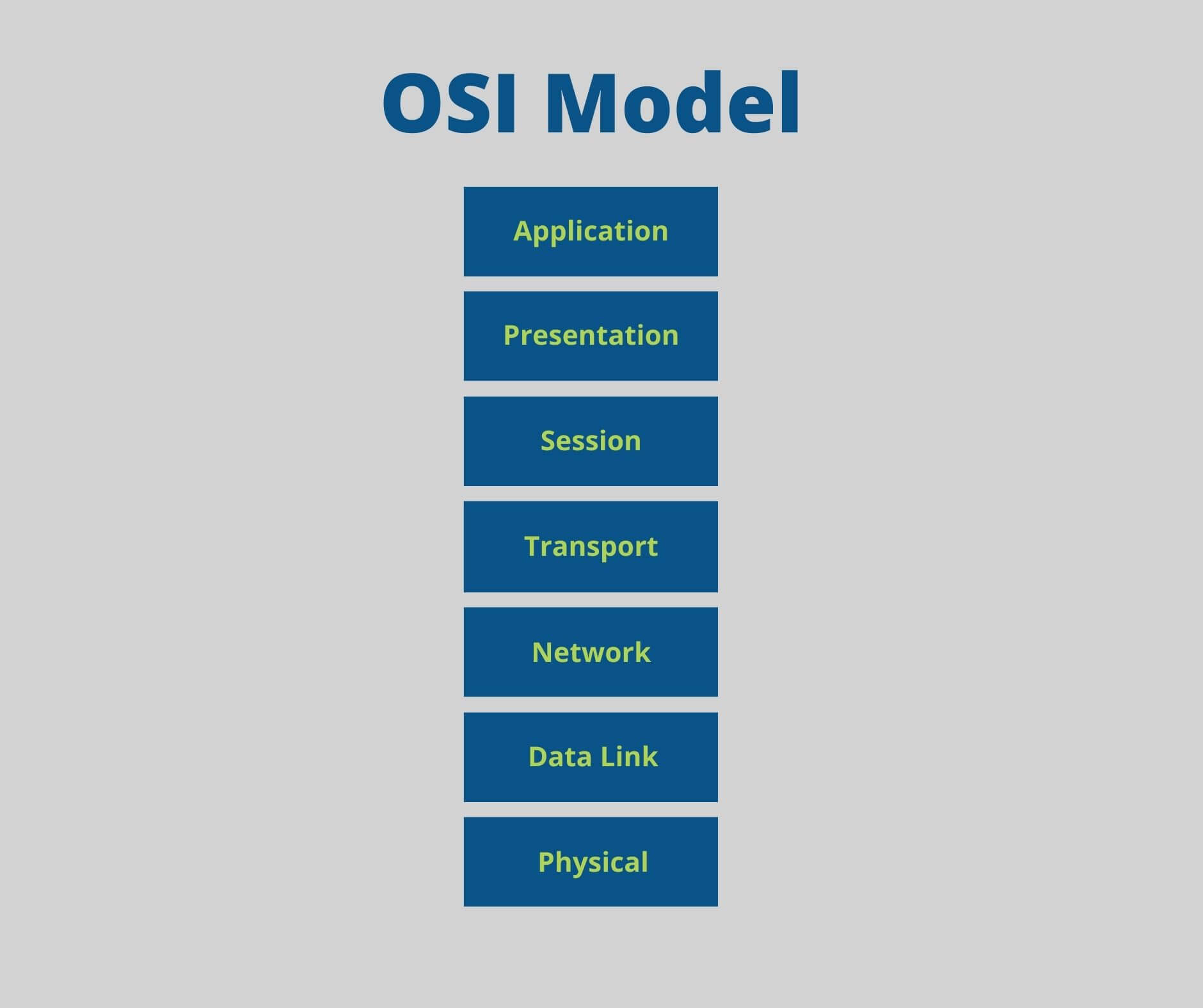

To understand how EtherNet/IP works, let’s take a step back. There is a basic framework that shows how network communications work, called the Open Systems Interconnection Reference model or OSI. The OSI model works to show how protocols interact, including with Ethernet/IP. Here is a diagram:

The OSI Model is divided into seven layers as shown above which are:

Application: This is the layer most end-users have the closest interactions with. This would include web browsers or applications such as Microsoft Office 365 or Outlook.

Presentation: The Presentation layer prepares the translation of the application data and format into network format. An example of this would be encryption and decryption of data for a secure transmission.

Session: A session occurs when two devices need to talk to each other. At this layer, logistics and termination occur.

Transport: At this stage, the logistics data transfer happens. The Transport layer is also known as the Transmission Control Protocol or TCP. The TCP is built on top of the Network (or IP) layer.

Network: The Network layer is where packet forwarding occurs between different routers. For example, if you’re connecting to a different server on the other side of the country, you’ll need to go through different paths. This is where the Network layer comes in.

Data Link: The data link layer is responsible for node-to-node data transfer.

Physical: You might’ve guessed that the Physical layer is where your electrical and physical components come in. This includes your cables, and ensuring sufficient voltages and frequencies.

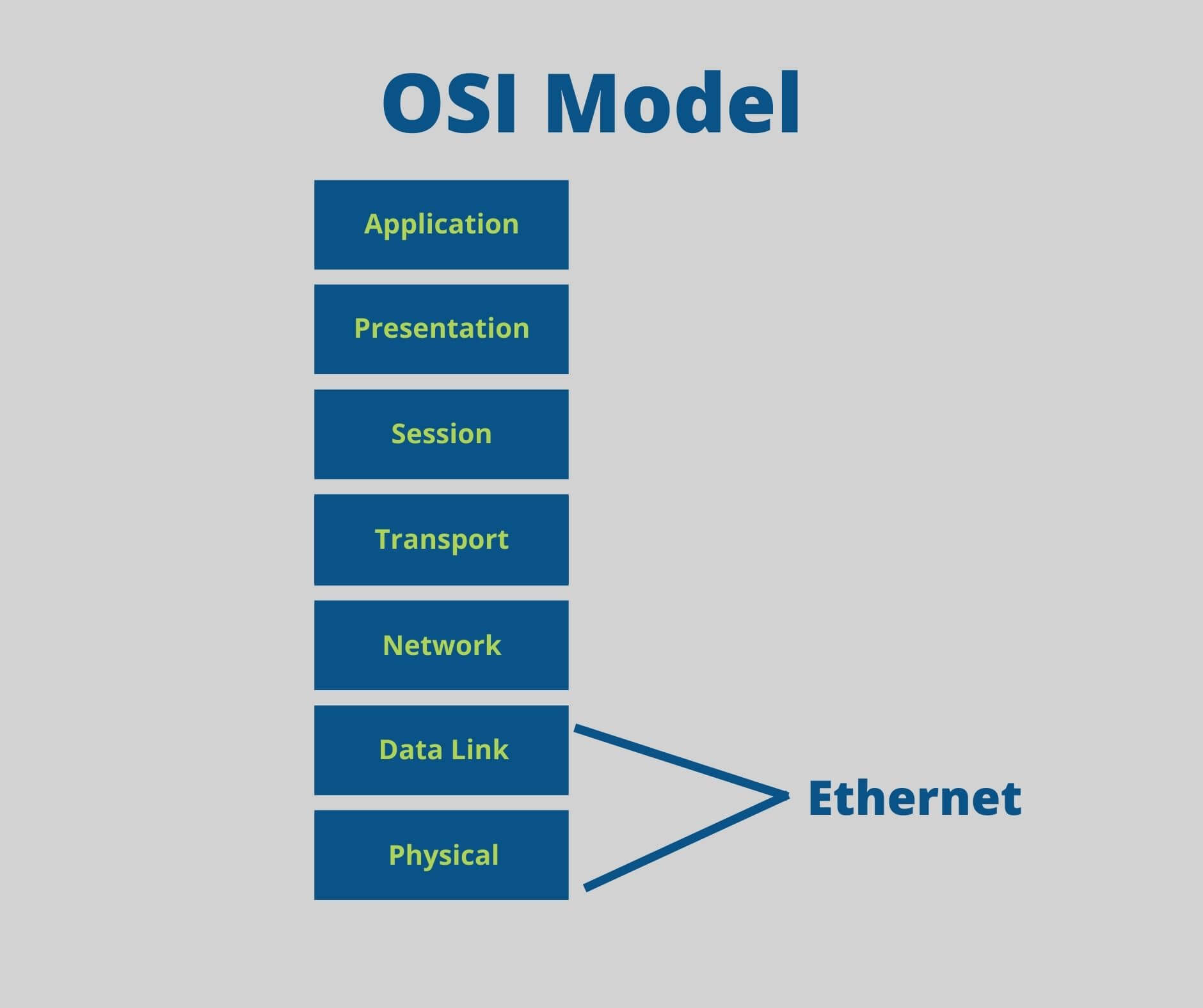

Note that Ethernet is at the data link layer and physical layer stage, since it’s your actual physical connection that conducts the node-to-node data transfer.

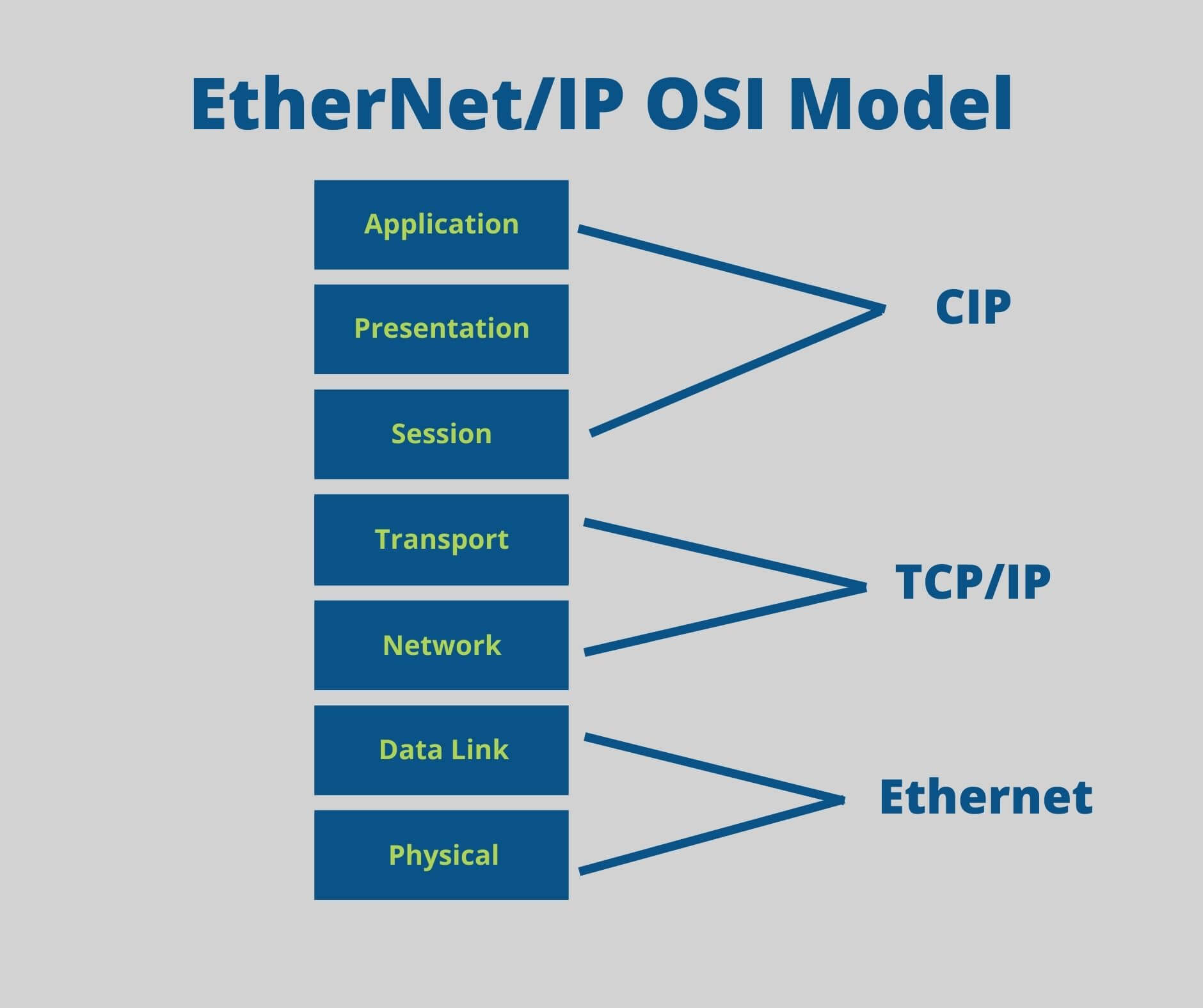

If we take the example of EtherNet/IP, there are three different layered protocols which include:

- CIP

- TCP/IP & UDP

- IP

At the EtherNet/IP level, EtherNet/IP will progress along different layered protocols through CIP layers to the TCP/IP and User Datagram Protocol (UDP) layer, and then finally to the IP. Here is an example of this with the OSI model below:

What’s the Difference Between EtherNet/IP and EtherNet/TCP?

As discussed above, both IP and TCP are layers that are part of the Ethernet stack. TCP is short for Transmission Control Protocol, which is used extensively with internet communications. IP is short for Internet Protocol and will forward the communications along.

Benefits of EtherNet/IP

Compatibility

EtherNet/IP is compatible with common protocols and transport devices using traditional Ethernet, making it easy to implement.

Standard

Ethernet has become a known certifiable standard to the point where devices must be required to be certified by EtherNet/IP test labs based on QoS.

Universal Use

Almost every industry has used EtherNet/IP to some degree, so its universality makes it a go-to protocol.

Support

Since EtherNet/IP has been around for decades, there are endless tools and training and vendors willing to help — including our tools and solutions here at Pyramid Solutions.

Utilizing EtherNet/IP

Across the globe, EtherNet/IP is the common industrial automation network standard for manufacturers. Companies that develop and manufacture industrial automation products understand that it requires extensive knowledge and training in order to successfully develop, test and deploy EtherNet/IP enabled products that meet the needs of their manufacturing customers. If you’re building your first EtherNet/IP project, click below to download our free EtherNet IP starter kit eBook, filled with what you need to know including how to get started, what to keep in mind for ODVA compliance, and even a workbook to plan your project.

In addition to our software solutions, we also offer various communication gateways, supporting multiple protocols, including:

Ethernet to DeviceNet

EtherNet/IP Adapter + Modbus TCP Slave to DeviceNet Master / Slave

Ethernet to J1939

EtherNet/IP Adapter + Modbus TCP Slave to J1939 (CAN)

J1939 to Modbus Interface

J1939 (CAN) to Modbus RTU Slave 2 wire RS485

Profibus to J1939

Profibus DP Slave to J1939 (CAN)

Profibus to DeviceNet

Profibus DP Slave to DeviceNet Master / Slave